Magnetic contactor is a vital component in industrial automation, providing a reliable method for controlling high-power electric motors and other heavy electrical loads. Unlike relays, which are used in low-power applications, magnetic contactors are designed to handle much higher voltages and currents, making them indispensable in large-scale industries. In this article, we delve into the fundamentals of magnetic contactors, including their structure, working principles, and key applications, to understand how they contribute to the safe and efficient operation of industrial power systems.

Table of Contents

What is a Magnetic Contactor?

A magnetic contactor is an electromagnetically operated switch. It is commonly used in large automation industries to control motors. Its function is quite similar to that of a relay, so you might wonder why we need both.

However, relays are generally used for low-power voltage, while magnetic contactors are used for high-power applications. You might have seen relays being used in small electronics projects, but in large industries, magnetic contactors are used for motor control and automation.

In simple terms, we can say that a magnetic contactor is a type of contactor used to start and stop power electric motors or loads.

Structure of a Magnetic Contactor

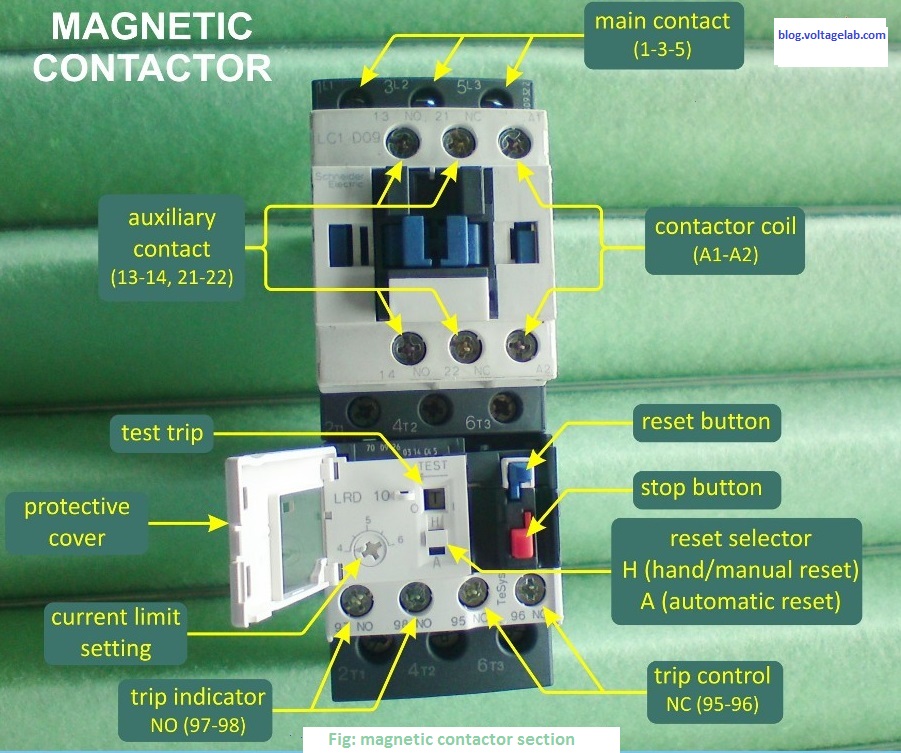

Its structure is quite simple. A magnetic contactor is composed of the following components:

- Main Contacts: These are primarily responsible for switching the power to turn the load on and off. There are 3 input terminals and 3 output terminals, which are labeled as L1, L2, L3 for the input terminals and T1, T2, T3 for the output terminals.

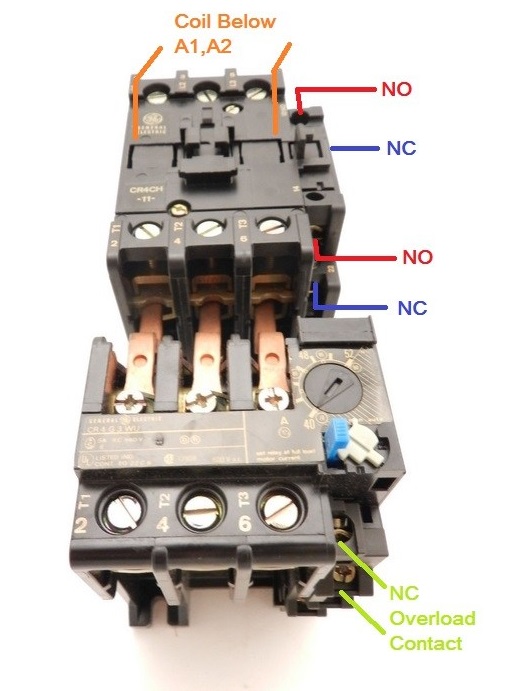

- Auxiliary Contacts: These contacts are generally used in control circuits. They are used to create automation or protection circuits for the load. There are two types of terminals: 1) Normally Open (NO) and 2) Normally Closed (NC).

- Power Supply Coil: This coil generates electromagnetic energy. When power is supplied, it energizes and turns into a magnet, switching the main contacts from normally open to normally closed condition. The coil terminals are labeled as A1 and A2. It energizes the solenoid and is available in different power supply ranges (24VDC, 24VAC, 110VAC, 240VAC, 415VAC).

- Auxiliary Block: This block is used to connect the auxiliary contacts. By using the auxiliary block, additional normally open and normally closed terminals can be created.

Discussion on Normally Closed and Normally Open Contactors

These contacts are auxiliary contacts. Normally Closed and Normally Open contacts are used to create automation or protection circuits for the load.

Normally Closed: In a normally closed state, when the coil is not energized, the auxiliary contact remains in a closed state.

Normally Open: The auxiliary contact remains in an open state.

Working Principle of a Magnetic Contactor

When current passes through the contactor, it generates an electromagnetic field. This magnetic field attracts the moving core.

The core of the contactor begins to rotate, which helps to energize the moving contact. The moving and fixed contacts create a short circuit, allowing current to pass through to the next circuit.

Initially, the armature coil carries a high current. As the current passes through the coil, it rapidly decreases. When the current stops, the coil becomes de-energized, and the contact opens.

Why is a Magnetic Contactor Used?

- A magnetic contactor allows for the safe and easy control of large motors or loads using a small push switch.

- The auxiliary contacts (Normally Open and Normally Closed) allow for various signals or status indications.

- It comes with an overload relay, which automatically interrupts the load current supply in case of overcurrent.

- Three-phase motors require a three-phase supply, which can be easily provided using a magnetic contactor.

- In a star-delta configuration, three magnetic contactors can be used for easy control.

- If power supply is interrupted during operation, the load current supply will stop. Even if the power returns, the load current will not resume unless the start button is pressed, protecting the device from surge voltage.

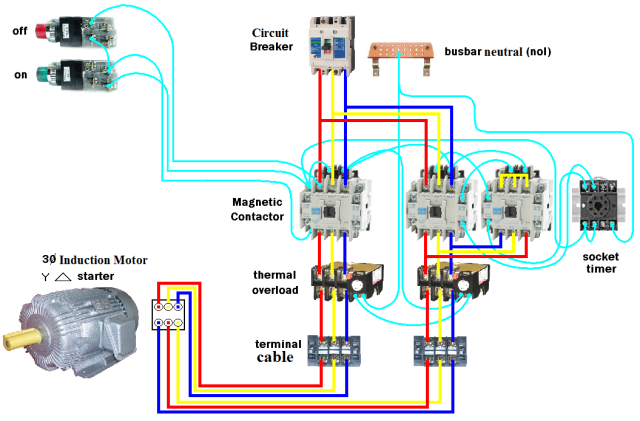

Wiring Diagram of Three-Phase Star-Delta Starter, Starter Motor Wiring Diagram:

FAQ

What is the purpose of a magnetic contactor in industrial automation?

A magnetic contactor is essential in industrial automation for controlling high-power electric motors and heavy electrical loads. It provides a reliable method for starting and stopping these components safely and efficiently.

How does a magnetic contactor differ from a relay?

While both magnetic contactors and relays are used to control circuits, relays are generally used for low-power applications, whereas magnetic contactors are designed to handle much higher voltages and currents, making them suitable for large-scale industrial use.

What are the main components of a magnetic contactor?

A magnetic contactor consists of several key components, including the main contacts (L1, L2, L3 for input and T1, T2, T3 for output), auxiliary contacts (Normally Open and Normally Closed), a power supply coil (A1 and A2), and an auxiliary block for additional connections.

How does the working principle of a magnetic contactor ensure safety in electrical systems?

The working principle of a magnetic contactor involves generating an electromagnetic field that controls the switching of contacts. This process ensures that electrical loads are safely managed, with features like overload protection and prevention of surge voltage damage.

Why is it important to use a magnetic contactor in three-phase motor control?

Magnetic contactors are crucial for three-phase motor control because they allow for easy and safe switching of the three-phase supply. They are also used in star-delta configurations for efficient motor control and protection against overcurrents.