Troubleshooting is a significant term in any kind of profession. Before solving a problem, you have to detect the cause or issue behind this. So, expertise is a crying need in this fact. But it’s not so easy to gain expertise in own profession. Time, dedication, patience is needful here. Today I want to discuss the PLC troubleshooting process.

What is Troubleshooting?

Suppose, you feel pain in the left portion of your chest. Then you feel worried and go to a doctor with a view to talking about this problem. The doctor will hear your problem attentively first. Then he will try to solve your problem. In this case, the doctor should know the pros and cons of heart diseases. Because the heart is located on the left side of our heart. Similarly, the engineer is also a doctor of machines. He should know the basic construction and functions of a machine for its troubleshooting. Then he can detect the problem of that machine.

How to Troubleshoot a PLC?

According to my above statement, we have to know about PLC before troubleshooting. Let’s know about PLC in a nutshell.

What is PLC?

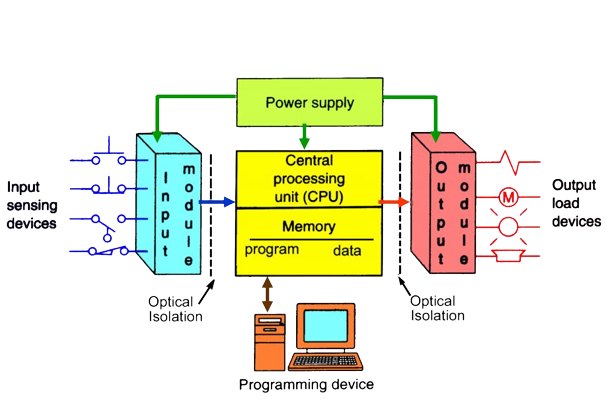

The full form of PLC is a Programmable Logic Controller. You can easily define this device using these three words. As Like:

- We can easily program this device and the device will run according to our instructions.

- It acts on the basis of a logic program that will be defined in software.

- It can control the output with the respect to input parameters.

Following these characteristics, we can say that PLC contains three parts basically. These are:

- Power Supply

- Input/Output

- CPU (Central Processing Unit)

Let’s know some techniques so that we can easily troubleshoot our patient PLC. Here I want to mention some problems of PLC.

Problem 1:

Suppose, your PLC can’t work according to your logic instructions. As a result, it becomes failure to show the desired output. What’s actually happened here? Let’s investigate.

Causes:

- It’s maybe the result of module failure of the input/output (I/O) system.

- There maybe the error in your logic instructions

Solution:

- We have to check the inner status of the I/O module.

- Check the logic instructions again attentively.

- Check the connectivity of PLC and computer device.

Problem 2

The PLC creates noise which is so irritating. Now let’s see the cause behind this.

Causes:

- Interference of external radio frequency signal.

- Poor performance of radio filter circuit.

Solution:

- Check the components of filter circuit.

- If your PLC has a close connectivity to any RF antenna then make a proper distance between them for removing noise.

Problem 3:

PLC goes on blackout out by losing it’s operating power. What’s to be done in this circumstances?

Causes:

- Power supply module problem

- Switch or electrical circuit panel problem.

Solution:

- Check the power supply module.

- Install backup power sources that activate when the primary power source becomes compromised.

Problem 4:

PLC memory can be corrupted at any time. In this fact, the ladder logic instructions will be unreadable by plc CPU module. What should we do in this case?

Causes:

- Unwanted RF frequency interference.

- Power disruptions.

Solutions:

Copying all data to a redundant storage device that is kept away from interference, high temperatures and humidity.

Read More Articles